Bulk liquid terminal management is a highly specialized, fragmented, and evolving industry for which accurate and timely data management is essential to a successful operation. The shift in communications is from paper files to email, chat and other electronic venues. Both paper and electronic communication systems have opportunities for data loss and disorganization, but without strict procedures in place data and knowledge stored electronically can be deleted, erased, and files may be lost. The bulk liquid storage industry is currently faced with the task of capturing and documenting practices and procedures developed previously in order to improve upon them and prevent loss.

Implementing an Enterprise Data Management (EDM) System that integrates both corporate (e.g. Sales data) with data from Plant Operations (e.g. a Logistics module) provides an IT solution to data management challenges faced by bulk liquid storage terminals. More importantly, it presents a unified picture to facilitate scheduling, planning and inform decision-making. Hardwired EDM’s may be older and provide added security, but increasingly cloud-based Software as a Service (S.A.A.S.) solutions are becoming the norm. Cloud based systems are cheaper to implement and provide terminal management and decision-makers with real-time (or near real-time) data from remote locations as well as from facility operations. The goal of these projects is to provide information that will increase Return on Assets (R.O.A.) by improving utilization, streamlining transport operations and identifying opportunities for automation.

The 21st Century has seen a rapid advance in technology applications for industrial use. The bulk liquid transportation and storage industries have only recently begun to invest in, implement and adopt the now available advancements in technology and integration. In the near future, competitive pressure will force the industry to develop solutions to further bulk liquid terminal data management in order to improve profitability, but there are obstacles to implementation.

These obstacles include:

- Facility size and complexity,

- Recent trends in mergers and outsourcing, and

- Personnel turnover.

Not to mention, the initial cost of the investment which includes the purchase price, implementation, and downtime.

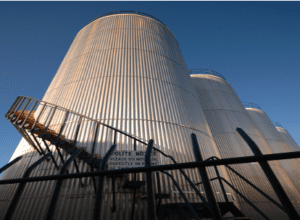

Bulk Liquid Terminals are Large, Complex Operations

Bulk liquid terminals are large aboveground storage tanks, also referred to as “tank farms,” where commodity chemicals are stored, such as crude oil, chemicals, and refined petroleum products before transport. They are often located near waterways. While every terminal differs, most provide or lease transport services for moving bulk liquids to the terminal from cargo ships or pipelines to tank trailers or tank rail cars. I n addition, some bulk liquid terminals provide value-added operations (packaging, canning, drum filling, and blending) which add to the complexity of the process operations, data sources, and thus the data management system. When operating a terminal, the amount and location of hazardous chemicals and bulk liquids must be accounted for on a daily basis to ensure appropriate levels of inventory, on-time delivery and customer satisfaction. In a large facility the number of data sources from operations [e.g. labor hours, inventory, and (product storage and transport)] and corporate [e.g. sales forecast, compliance] to be analyzed, interpreted and acted upon is quite extensive. Having knowledgeable personal available to assess the data is necessary in order to efficiently manage the inventory, allocate labor resources and optimize the utilization of equipment.

n addition, some bulk liquid terminals provide value-added operations (packaging, canning, drum filling, and blending) which add to the complexity of the process operations, data sources, and thus the data management system. When operating a terminal, the amount and location of hazardous chemicals and bulk liquids must be accounted for on a daily basis to ensure appropriate levels of inventory, on-time delivery and customer satisfaction. In a large facility the number of data sources from operations [e.g. labor hours, inventory, and (product storage and transport)] and corporate [e.g. sales forecast, compliance] to be analyzed, interpreted and acted upon is quite extensive. Having knowledgeable personal available to assess the data is necessary in order to efficiently manage the inventory, allocate labor resources and optimize the utilization of equipment.

Industry Trends Contribute to Terminal Data Management Challenges

Merger and Acquisition activities and joint ventures such as, Kinder Morgan, DCP Midstream, and Targa Resources Corp. agreement to move forward with the Gulf Coast Express Pipeline Project, complicate technology implementation and information retention. Combining data systems after a merger requires skilled data analysts and network implementation experts working closely with employees who have a deep understanding of the operations in order to know which of the new company’s data is important to integrate for the success of the venture.

Outsourcing is another trend that can complicate data acquisition. Obtaining important data from an outsourced vendor requires excellent communicators to handle the negotiations. Trust and cooperation among both parties are mandatory. It requires management commitment from both the vendor and the terminal to identify relevant data sources and allocate the time and resources for a successful transfer of the data leading to a more timely and efficient supply chain.

M&A activity, outsourcing, and the aging of the workforce all may result in turnover leading to less experienced managers taking on additional responsibilities and making important and costly decisions. In addition, with the baby-boomers retiring, hiring qualified replacements for engineers and technical experts whose skills are in high demand is difficult. Ironically, it’s these new employees and potentially less experienced leaders who rely most heavily on data from the IT management system and the collected information available. Being able to transfer information to new managers and technical personnel quickly and accurately is a key-function of the data management system once it is in place. However, if a system is not yet in place, the loss of readily available knowledge of processes and equipment may slow the implementation.

The loss of corporate institutional knowledge is a challenge which executives who make decisions at the highest level of the organization need to recognize and prepare for prior to executing major changes in corporate structure and facility operations. If left unaddressed, these challenges will lead to inefficiency and extend the expected time to realize a return from these activities. Improved efficiency and increased profitability are worthwhile goals, and having an appropriate data management strategy prior to executing these activities will benefit the company, suppliers and customers.

Improving Efficiency of Bulk Liquid Storage

In 2017 and beyond, terminal management systems need sound practices for operation management, asset management, safety, compliance, and reporting to manage the growing complexity of the industry effectively across business units, supply chains partners, customers, and vendors. Logistics and data management should not be considered isolated processes of terminal management systems, as they are key factors in keeping terminals running smoothly and profitably. A well-developed, integrated, and efficient logistics data system for bulk liquid terminal management will identify opportunities for improved profitability, increase asset utilization, and provide decision-makers with the information required to meet current and future customer product expectations.

At Penn Intermodal Leasing, LLC we are committed to delivering our bulk liquid transportation chassis quickly, efficiently, and on time to help your company achieve their goals. Contact us today for more information!